Having briefly touched on the topic of deep-cycle batteries in our article on dual-purpose batteries last month, now seems like a good time for a more in depth look at these often-unsung heroes of work and play. Sort of like a janitor, you only notice them if they’re doing a poor job. These days deep-cycle batteries are used in so many applications, it’s no wonder the industry registers in the multi-billion-dollar range. From recreation like golf carts and RVs to heavy industry like forklifts and UPS systems, deep-cycle batteries are everywhere, keeping the world running. At this point, it’s safe to say we could not live without them.

The simplest definition of a deep-cycle battery is a battery that can be discharged constantly until it reaches the maximum depth of discharge recommended by the manufacturer and then recharged before the process is repeated again and again. A car battery could never be subjected to this type of application and last very long. But why?

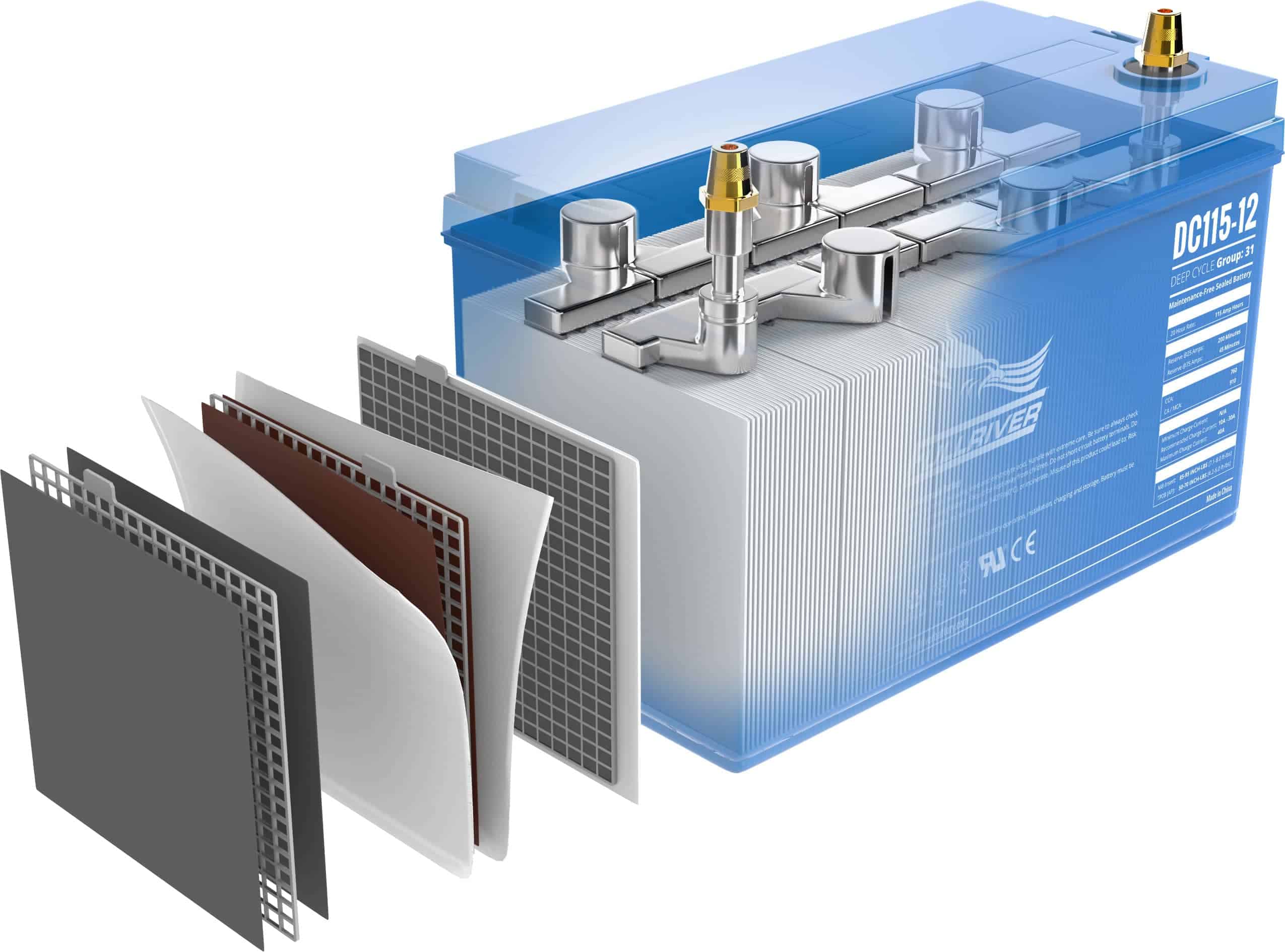

Served on a Plate, or by a Plate

A true deep-cycle battery will differ greatly from most standard automotive batteries due to the composition of the individual plates inside the battery. Automotive batteries utilize sponge lead, lead that has gone through a special process so that it becomes like a sponge. Sponge lead has a lot more surface area which allows for energy to flow out of the battery more readily for cranking an engine. The downside of the material is that it’s weak and subject to rapid sulfation.

Most deep-cycle batteries are made with flat plates, or in some cases cylindrical tubes. If the battery is well made, these plates, thick with ample active material, are well cured so they’re neither brittle nor mushy. Curing time is critical to ensure long-life and resilience. Some manufacturers cut corners and the curing process is rushed which can lead to early failures. Remember Murphy’s Law. Fullriver plates undergo a 10-day curing period, one of the longest in the industry where the standard is 1-3 days.

A Tight Fit

After the plates are finished, they are ready to be installed in the battery case. For a typical flooded cell battery, they are simply set into place. But for an AGM battery, the glass mat material is intentionally bulky and must be compressed to fit into the case. Once the electrolyte is added to the cells, the glass mat expands, further wedging the plates into the cell housing. This greatly mitigates against the inherent vibration of applications like electric vehicles, or a pallet jack going down the road in the back of a semi-truck.

Connections

The next step in assembly is to connect each of the individual 2-volt cells in the battery together to whatever nominal voltage the battery is supposed to be. 3, 2-volt cells for 12 volts, 4 for 8 volts, 6 for 12 volts, and so on, ad infinitum. Most manufacturers accomplish this inter-cell connection by punching a hole between the plastic separators (partitions) that divide these cells, and basically bolting the cells together. This method has one serious short-coming, upward movement of the cell pack. If a battery bounces up and down, the cell connection is subjected to stress where the partition inhibits this movement, and a dropped cell is common. Instead of a 12-volt battery, you’re left with a 10- volt.

Fullriver uses a method of cell interconnection called over-the-partition (OTP). Instead of punching through the plastic partition, the cell connections go over each partition. By linking each cell with OTP welds, if the cell pack wants to move upward, the inter-cell connections are not stressed by slamming into the plastic partition. That’s not to say the pack is free-floating, it’s just allowed some wiggle at these critical connection points.

The thing about battery cases…

The case of the battery is the next critical component we shall examine. It doesn’t sound very exciting, but you can be sure it matters more than you might first imagine. Have you ever been told not to put a battery on concrete? That’s not true anymore unless you have a battery that’s really old but was related to the type of case batteries used to be made with, rubber. Today, battery cases are made from a few different materials.

Many automotive and some deep-cycle batteries use polypropylene cases. To begin, PPO is not very puncture resistant. The lid on a PPO case is heat sealed to the top of the battery. Heat-sealing is problematic because it is vulnerable to failure when in hot environments. In the case (pun intended) of a valve-regulated battery this weakness effects the overall operation of the battery. The psi rating of the valves on top of the battery, which allow air and moisture to escape the battery, cannot be too high or there’s a risk of case failure, either by rupture or deformation. In turn, the lower psi setting of the valves allow them to open more often, which allows for more moisture to escape from the battery. When a sealed battery dries out, it’s game over.

Fullriver battery cases are made with ABS plastic. While that may not sound very sexy, ABS solves a lot of the problems inherent in PPO. First, the lid can be epoxy sealed to the case, which is much stronger. If you want to take the lid off an ABS case, get out your angle grinder, because it’s not going anywhere otherwise. This allows for, you guessed it, higher psi settings on the valves. The valves open less frequently and thereby retain more water for the life of the battery. Oh, yeah, and ABS is incredibly resistant to drops and punctures.

DoD: Dispatching Myths

It is all too common today to be reading on some forum or in the marketing literature of a “new battery technology” that deep-cycle batteries cannot be discharged more than 50% of their rated capacity. In other words, they would have you believe that a 100Ah battery is really only a 50Ah battery because one must never discharge below 50% (Gasp!) If you happen to own a battery and the manufacturer has stated not to discharge below 50%, by all means follow their advice. Generally, with most respectable manufacturers, they allow for discharging to at least 80%. Every Fullriver battery is life cycle tested to 100% DoD. Meaning, every battery Fullriver makes, is tested from day one to its full rated capacity, 100% DoD, until it finally gives up and quits.

Shotgun

We’ve examined some of the more critical parts to a true deep-cycle battery. However, there are so many other things that Fullriver does to ensure the highest quality, longest lasting deep-cycle battery that it’s just not practical to examine every one of them in fine detail. In passing, here’s a few of the other details worthy of mention. All Fullriver batteries in our DC Series have a 10-year design life. All our terminals in the DC Series are made of highly conductive brass to reduce heat/resistance. Our batteries offer some of the highest cycle life in the industry. For longer life, and faster charging, we use 99.994% pure lead in every battery we make.

And that, in our experience, is what make a true deep-cycle battery. Attention to design details, rigorous manufacturing standards, and the best components. It’s not any one thing by itself, but the sum of its parts that makes it great.

I find it interesting when you said that the cases of deep-cycle batteries are made from polypropylene. I wonder if that is the same with a lightweight AGM battery and if it matters as well. In my opinion, every material being used for various products would probably be important to ensure the safety of their usage. https://concordebattery.com/about/lightweight-agm-battery-from-concorde-battery-corporation.html

Your in-depth exploration of deep-cycle batteries sheds light on their critical role, often overlooked, in various applications. The comparison to a janitor, noticed only if they’re not doing their job well, effectively conveys the unsung hero status of deep-cycle batteries.

The detailed breakdown of the construction process, from plate composition to inter-cell connections, provides valuable insights into what makes a reliable deep-cycle battery. The focus on Fullriver’s meticulous approach, including the 10-day curing period, over-the-partition cell interconnection, and ABS plastic cases, emphasizes the importance of quality in manufacturing.

Addressing common misconceptions, especially the myth about limited discharge capacity, adds clarity to the discussion. Your clarification on Fullriver batteries being tested to 100% Depth of Discharge (DoD) reinforces their reliability and durability.

Highlighting additional features like the 10-year design life, brass terminals for conductivity, and the use of 99.994% pure lead further establishes Fullriver as a brand committed to quality and longevity.

This insightful article not only educates readers on the intricacies of deep-cycle batteries but also serves as a testament to Fullriver’s commitment to excellence. Deep Cycle Batteries is a valuable resource to explore further. Great job!