In a world full of lithium and TPPL, Fullriver’s Class III power pack, the PowerVault, shows real resilience in real-world situations. Fullriver has been making deep-cycle batteries since 1995, and in 2017 we combined our deep-knowledge of batteries with the best available components to bring our own Class III pack to Material Handling. Going on 7 years with this product in the market, we thought it was a great time to reflect on what makes the PowerVault Series so worthy of serious consideration.

Dirty Environments

We know there are some very messy workplaces out there, especially where food production is concerned. Our DC224-6s are sealed, include stainless fasteners to resist corrosion, and are installed in a high-quality powder coated steel case. Throw in the IP65 rated IC650 charger and you end up with a pack that is power-wash ready, designed to resist dust and water ingress in bakeries, meat or fish processing plants, breweries, and other messy environments.

Rocky Roads

The real-world is full of rough roads and a tractor trailer isn’t known for the smoothest ride. Many packs on the market utilize thin plates, other battery plates dangle in a gel solution, and the newest technology depends on sensitive electronic boards to keep them working. The internals of all Fullriver batteries are engineered to flow with the bumps of over the road transport. Over the partition cell connections ensure the cell block can float unimpeded, thick plate cells better resist vibration, while cells packed under compression greatly reduced the impacts of jarring on the battery plates. All of this is wrapped up in an ultra-tough, spill-proof ABS case.

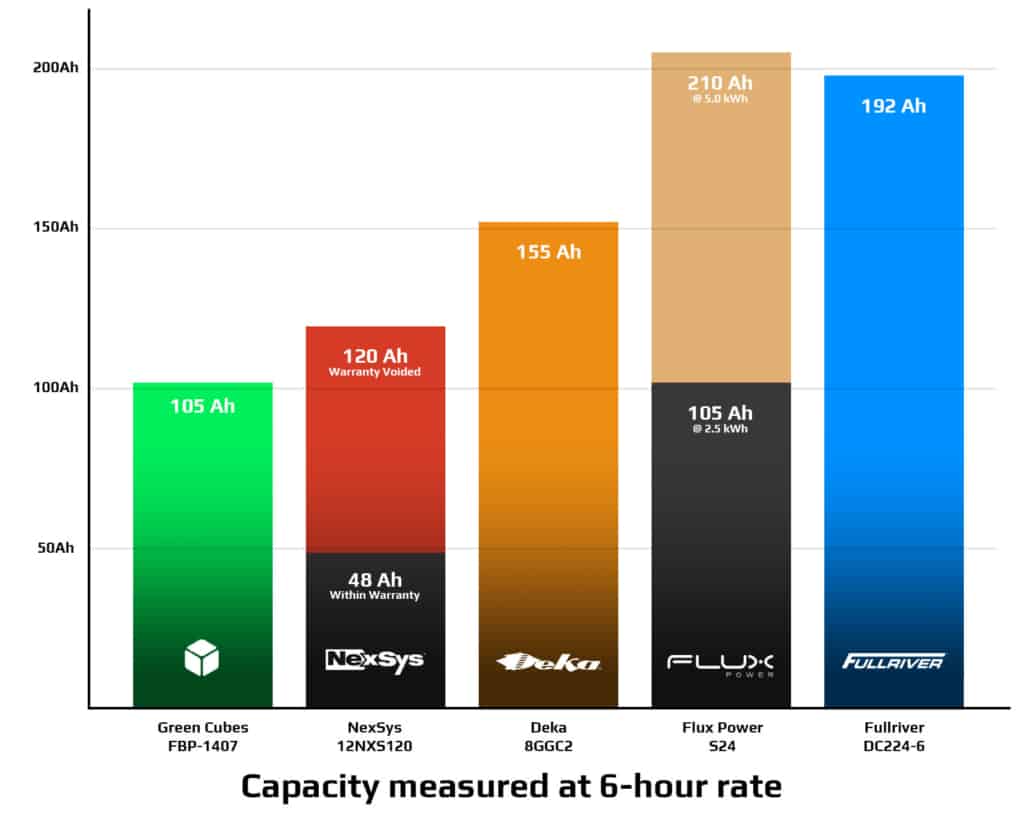

Higher Capacity for Long Travel Requirements

In a packed urban context, Fullriver powerpacks offer true deep-cycle capabilities when deliveries are over blocks, not just docks. The workhorse of the PowerVault is our 224Ah GC2, the DC224-6. While some of the most prominent pack builders limit usable capacity to 40%, our heavy duty, thick plate batteries are designed for 100% usable capacity. And while some manufacturers encourage opportunity charging to boost their limited capacity packs, the PowerVault, with plenty of usable capacity eliminates this need. Let’s be clear, opportunity charging equals downtime. In fact, the PowerVault boasts some of the highest capacity for a Class III pack. Don’t settle for low-capacity packs, when the PowerVault will go strong throughout the workday.

Murphy’s Law

In the real world, sometimes things go wrong, and when they do, how will they be resolved? Can the pack be repaired on site, or does it need to be shipped back for repairs? Are the critical parts readily available and nearby? Is the repair process simple and straightforward, or does it require specialized training? Fullriver batteries come in popular BCI standard group sizes, no odd, hard to find proprietary fitments. If something does go wrong, every component in Fullriver powerpacks is field-serviceable to minimize unforeseen downtime, and readily available through our network of distributors and dealers across the US and Canada.

Knowledge Insight is Power

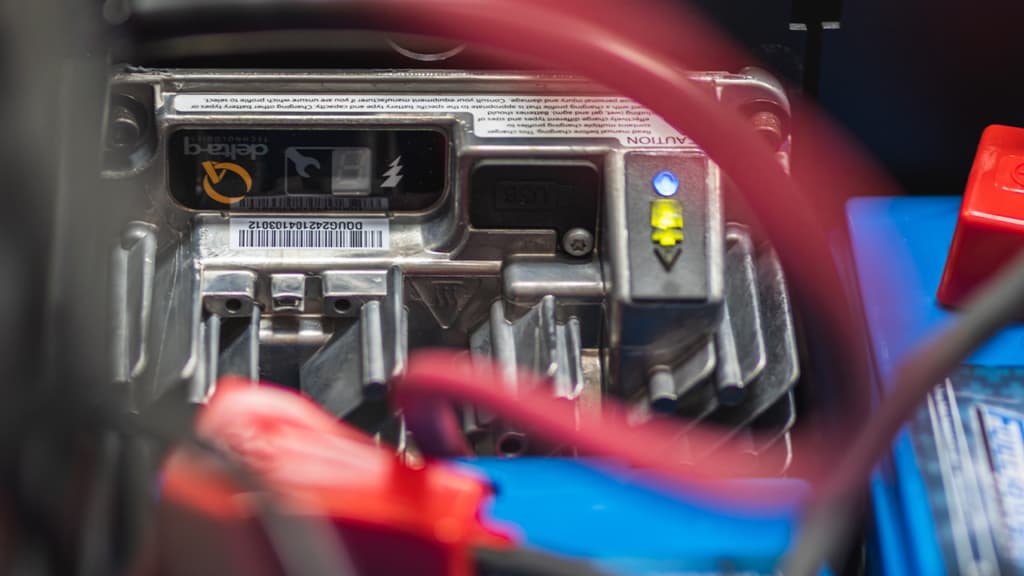

Sometimes understanding a specific operation, its workflow, usage and charging habits can be highly valuable. Scheduling time for a site visit can take weeks. The PowerVault comes standard with built-in data acquisition via the Delta-Q IC650. Data can be obtained in 30 seconds and sent instantaneously via email for fast feedback. Event logging drives insight for Dealer and Customer. Understand user habits, address inefficiency, to help customers succeed in their operations.

But wait… there’s more!

We said Top 5, but there’s yet another reason to consider the PowerVault! Fullriver doesn’t just tout its PowerVault as great, we stand behind every pack we sell with an industry-leading warranty and none of the red tape many manufacturers impose. Our flagship PowerVault is backed up by a full 2-year warranty, and the ultra-long-life EGL PowerVault comes with a full 4-year warranty!

The Real Deal

The Fullriver PowerVault goes beyond marketing hype and the promises of a sales rep, delivering in the real world the best performing, most robust pack in the industry. Engineered for messy, bouncy, tough environments, to provide years of reliable power. If you want to reduce costly downtime in your fleet of pallet jacks, reach out to Fullriver Battery today.

We are interested in purchasing for our manliftts and minicranes/

Jeff, thanks for your comment. Please send us your contact info here: info@fullriverbattery.com and we’ll be in touch.

Regards,

Aaron

Great article! Great battery!