Not long ago, in western Montana, a team of firefighters with their engine, were heavily engaged fighting a forest fire. The blaze was intense, and soon was overtaking the team. The heat from the fire grew so intense that it caused the tires on the truck to rupture, and they retreated, driving out with no tires to speak of. When they eventually got back to the station, they inspected the vehicle and were amazed to find the battery pack was in perfect form. The batteries were Full Throttle FT1100-31’s. Fire, police, ambulance, ocean rescue, and even military everywhere are turning to Fullriver/Full Throttle to get the job done in their demanding applications.

Perhaps the most veritably critical of all applications are those of first responders and emergency services. In particular, the batteries used in emergency vehicles, with lighting, radios, computers, and engines hanging in the balance, the battery is the lynchpin of an effective operation. The battery also happens to be one of the most taxed in its role of keeping everything going. Fleet managers for fire, rescue, and police know these factors all too well and have come to demand resilient solutions. Let’s breakdown some of these challenges and look at what it takes to perform when it counts most.

Environment: Hot and Cold

Emergency vehicles don’t get snow days or shy away from heatwaves, these are often the times when they are needed most. Whether it’s a roaring blizzard or a raging wildfire, emergency responders are plunged right into the middle of nature’s worst conditions. When the weather is extreme AGM batteries like Fullriver/Full Throttle stand strong due to a “starved electrolyte” design, meaning there is very little water in the battery to begin with. The cold has less effect on the battery than a conventional battery that is filled with liquid electrolyte. Even in bitter cold, the thin-plate, pure-lead grids of Full Throttle allow starting power to flow with ease.

This goes for the heat as well, though most hot-start issues are related to other engine issues, the PHCA (Pulse Hot Cranking Amps) that a Full Throttle battery produces is a huge aid when an engine is hesitant to turn over in the heat.

TPPL for handling surges in demand and Cranking Large Engines

Most vehicles (excluding police cruisers) used for emergency services, are powered by a diesel engine. Diesel engines have very high compression and are challenging to start, especially in the cold season. The plate structure in Full Throttle batteries is known as Thin-plate, pure-lead (TPPL). These plates are comprised of thin strands of lead alloy that create a lot of surface area for the energy to flow in and out of the battery. Not only does this allow for plenty of cold cranking amps, but once the engine is started, the plates have excellent charge acceptance, so the battery is recharged quickly without a lot of resistance. TPPL also allows the battery to handle surges in demand from auxiliary equipment such as a winch, without putting much strain on the battery.

Ultra-Safe and Maintenance-Free

It would be just a bit ironic to have an emergency vehicle have its own emergency due to a catastrophic failure in the battery. Fullriver/Full Throttle batteries are safer by design. Incidents of thermal runaway are very rare in AGM batteries. The electrolyte, sealed in a heavy-duty case, will not spill if tipped over, shaken, or thrown down a flight of stairs. While the ABS case itself is very difficult to puncture. If they were, somehow, punctured the electrolyte inside is not free flowing. And, in all but the rarest of circumstances, the batteries do not emit hydrogen gas or sulfuric acid. All these failure modes can and sometimes do occur in other battery types.

The flipside is only upside as well. When there’s no watering required to maintain a Fullriver/Full Throttle battery; there’s no corrosion, no need to clean the battery or change the cables due to off-gassing corroding them, then there’s no downtime, and no interruption of the important work to be done.

Shelf-Stable

Some departments have equipment that may be used infrequently and can sit unused for months at a time. All Fullriver/Full Throttle batteries have a very low rate of self-discharge that solves this issue (I.E., low internal resistance). This is due to the high purity of lead we use to produce our batteries. Simply charge the battery fully before storing it, and resume use when the equipment or vehicle is needed. That’s all.

Long hours: Proprietary plates/active material to recover from deep discharges

Often, time on scene for emergency responders can drag on for hours. In some scenarios, the engine is turned off while the electrical burden from the equipment must be borne solely by the battery pack. In these situations, the batteries may be called on to exceed their ratings, it’s just part of the job. Fortunately, the special materials and processes used to build every Fullriver/Full Throttle battery are unique and lend the batteries a special resilience so they can tolerate abuse and recover well with a good recharge. Our plate curing process, which ensures the plates and active materials hold up, is more than three times the industry standard. The high purity of the lead we procure and the proprietary processes we employ in preparing and forming our plates ensure the best chance of survival and long life in the face of such demands.

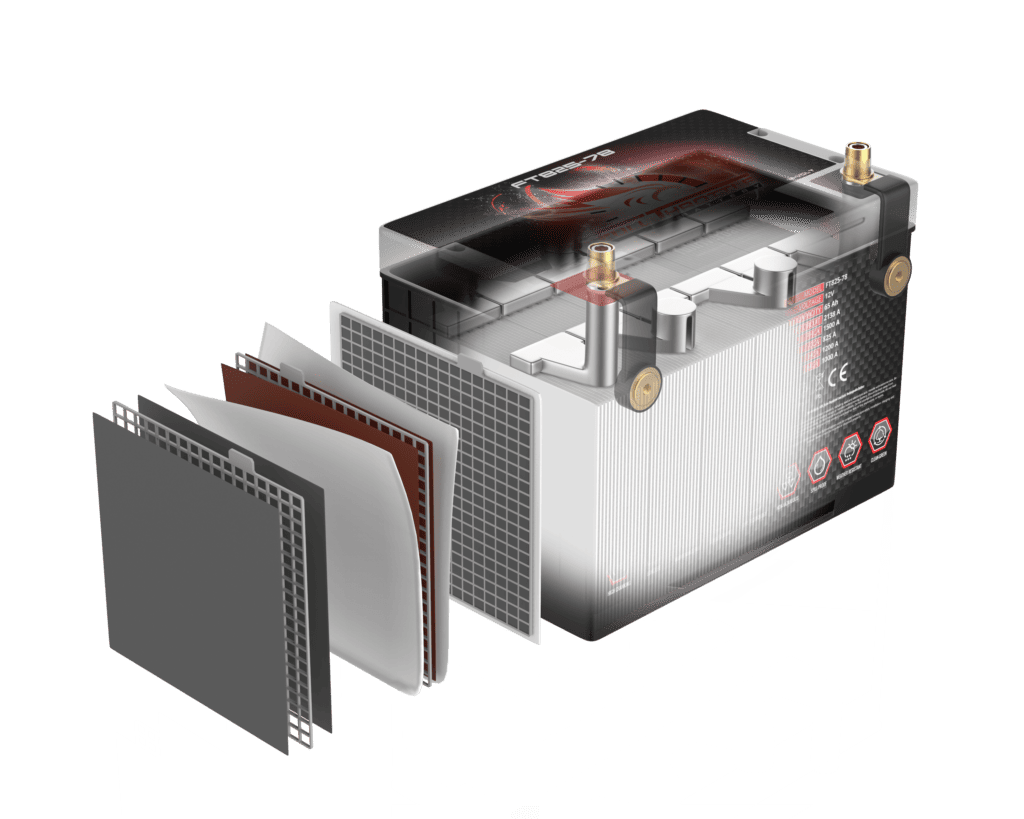

Vibration: High speeds, on and off-road conditions

Racing to the scene on bumpy roads, or off the road; when response times are measured in minutes, the right batteries for the job must be designed to stand up to vibration. The fact is most conventional batteries aren’t designed to take the enormous forces produced in intense driving scenarios. The internals of all Fullriver/Full Throttle batteries are engineered to handle vibration. Looking at a cross-section of the battery reveals cells that are packed under compression to reduce the effects of vibration forces. Additionally, the connections between each battery cell are designed to be unimpeded when up and down forces are applied to the battery reducing the likelihood of internal shorts (dropped cells).

The job of first responders is vital. The demands of the work require a resilient battery that will stand up in the real world, uncompromised by weather, rough roads, long hours, but ready at all times to deliver when called upon. Every battery made by Fullriver/Full Throttle is equipped with all that will be needed to succeed, just add heroes.